How ready is the world with bioplastics? Bioplastics are made from biomass feedstock, and the resins produced with biodegradable feedstock are much better for the environment. We are now producing much higher quantities of bioplastics, too.

What are bioplastics?

Bioplastics are derived from different renewable sources of raw material. Unlike regular plastics, bioplastics are evaluated as a little better on the environment because they can be made of sugars and starches.

Some examples of bioplastics include partially bio-based plastics or bio-based plastics, biodegradable bioplastics, and plastics made partially of fossil fuel raw materials but are made to biodegrade them partially.

Bio-based PE is an example of a bio-based plastic that possesses identical characteristics compared to its more conventional, fossil-fuel-based counterpart. If we compare the mechanical properties of bio-based PE to fossil fuel-based plastic, they would be the same.

The difference is that biodegradable plastics will eventually degrade over time. They are placed in a proper facility where the bacteria that can consume the bio-based plastic can thrive and eventually break down the bio-based plastic to its constituent elements.

The bioplastic definition is often confusing because there are many plastics classes. For marketing purposes, many manufacturers and retailers use the name “bioplastic” to imply that their plastic wares will biodegrade naturally over time, without further human intervention.

To be clear, the bioplastic advantages are only there when bioplastics can be routed to a proper facility. Bioplastics will only degrade over time with the right temperature, in the right facility, and in the presence of the good microorganisms that can tackle the task of breaking down the bioplastic for good until all that remains are water and carbon dioxide.

Producing bioplastics is expected to significantly impact the dependence on petroleum byproducts for the production of resins in the next five to ten years.

By 2025, it is expected that petroleum consumption for producing plastics can be reduced by as much as 20%. Europe and Asia have markedly increased demand for plastics, and these two regions will also have the largest share of bioplastics production in the world in the coming five years.

The market growth for this sector has been marked at a maximum of 15%, which is still some ways to go, if we are thinking about making a dent in conventional plastics’ current environmental damage. Bioplastics provide a small window of opportunity to reduce plastics’ impact on the world’s oceans and, of course, the land.

Since the beginning, humans have added more than nine billion tons of resins and plastics to the earth’s surface. Nearly 170 million tons of plastics are already in the ocean, and annually, we add almost ten million tons repeatedly. The rest of the plastic waste remains on land, in different landfills, incinerators, and the like.

It takes more than five centuries at most for plastics to completely degrade, but the rate is much too slow for comfort, and plastics are changing the face of the earth and how the environment looks and functions. Bioplastics’ introduction is a good step since the raw materials are changing, and bio-based resins are now less likely to destroy the earth. The resins are made with less toxic compounds, too.

What Is Meant by Bioplastic?

Bioplastic products are made from plastics that are manufactured from various renewable sources. The most common source of biomass for bioplastics is sugarcane, while other manufacturers use corn and yeast. Bioplastics are special among the many types of resins produced for the world market because biological processes can eventually break them down.

Essentially, bioplastics can help put a stop or pause in the use of fossil fuels for resin production, but only if they are globally and widely adopted. Bioplastics (the real ones) don’t just break down physically, they can also degrade to their constituent parts, and they are also biocompatible with the environment.

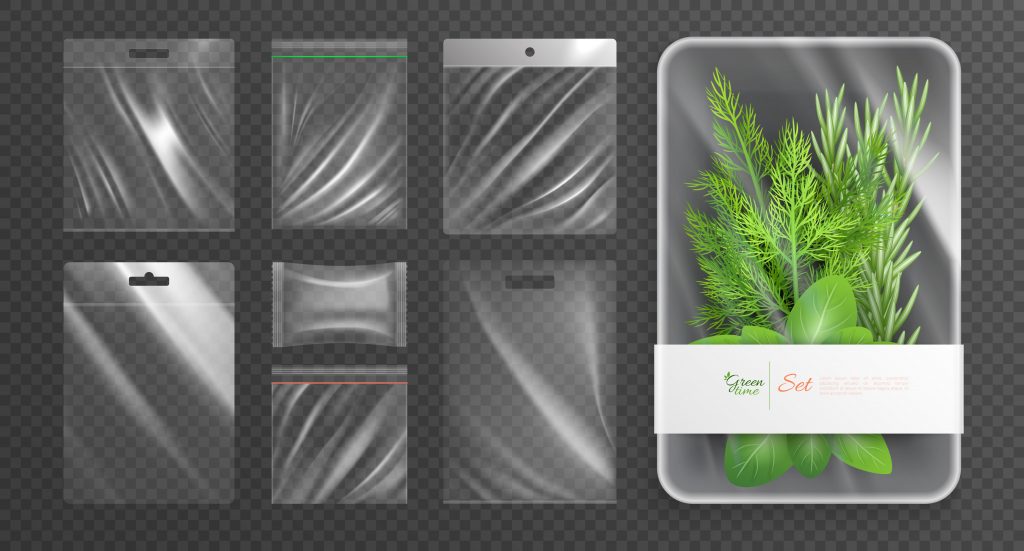

Bioplastics have become essential in many productive industries, including those producing food packages, agricultural supplies, horticultural supplies, etc.

Many companies produce compositing bags that are also made of bioplastics – these will naturally degrade and not harm the environment as they are sunk into the earth.

Keep in mind, however, that not all biodegradable resins or plastics can be composted.

Several major bioplastic resins are created from sugarcane and corn, like thermoplastic starch, cellulose acetate, and polylactic acids. Conventional plastics can also be manufactured from microalgae, as these naturally produce byproducts that have a high percentage of proteins and carbohydrates.

For example, Spirulina can have 63% protein, while Chlorella has up to 58% protein when dry. Bioplastic production from algae is seen as a worthy channel for more research and development.

Based on a survey of almost 300 corporations focused on resin production, there will be a sizeable shift to creating more bioplastics. By the year 2020, it has already happened that bioplastic production was already up by twelve million tons. The current volume is a 1% shift since 2011.

The demand for bioplastics is increasing but not enough to double the current volume of production. It has also been estimated that bioplastic production will increase greatly in South America and Asia before anywhere else. This is because there is a much higher need for single-use plastic products in these regions than anywhere else because of the economic capacity of people.

What Products Are Made from Bioplastics?

Bioplastics are used for so many industries and markets because they possess the same mechanical properties as traditional resins or plastics made of derivatives from fossil fuels.

Bioplastics are now found in biomedical products, electrical products, structural materials, etc.

With the never-ending demand for plastic alongside the rallying call for more environmental-friendly plastic products, it’s not unusual to find more bioplastics in the things you buy and use nowadays. Whether or not the world will turn fully to bioplastics depends on how it is further developed and embraced.